Leave Your Message

In the evolving landscape of industrial efficiency, the utilization of a Compressed Air Heater has become increasingly vital for optimizing operations. According to a recent report by the Compressed Air and Gas Institute (CAGI), nearly 70% of industrial facilities utilize compressed air systems, with heating capabilities being a crucial factor in enhancing energy efficiency and system performance. As industries seek innovative solutions to reduce energy consumption, the role of a Compressed Air Heater in maintaining optimal air temperature during processes cannot be overstated.

Expert in industrial compressed air systems, Dr. Emily Hart, states, "Implementing a Compressed Air Heater can significantly increase the efficiency of pneumatic operations while also extending the lifespan of equipment." The potential benefits are staggering, as studies suggest that an efficient heating system can result in energy savings of up to 30%, which translates into substantial cost reductions for manufacturing companies. With rising energy costs and environmental concerns, the adoption of such technologies is not just beneficial but necessary for competitive advantage in the market.

In conclusion, the integration of a Compressed Air Heater into compressed air systems promises enhanced performance, operational cost savings, and a reduction in environmental footprint. As industries continue to innovate, understanding the benefits and key considerations of this technology will be essential for achieving long-term operational efficiency.

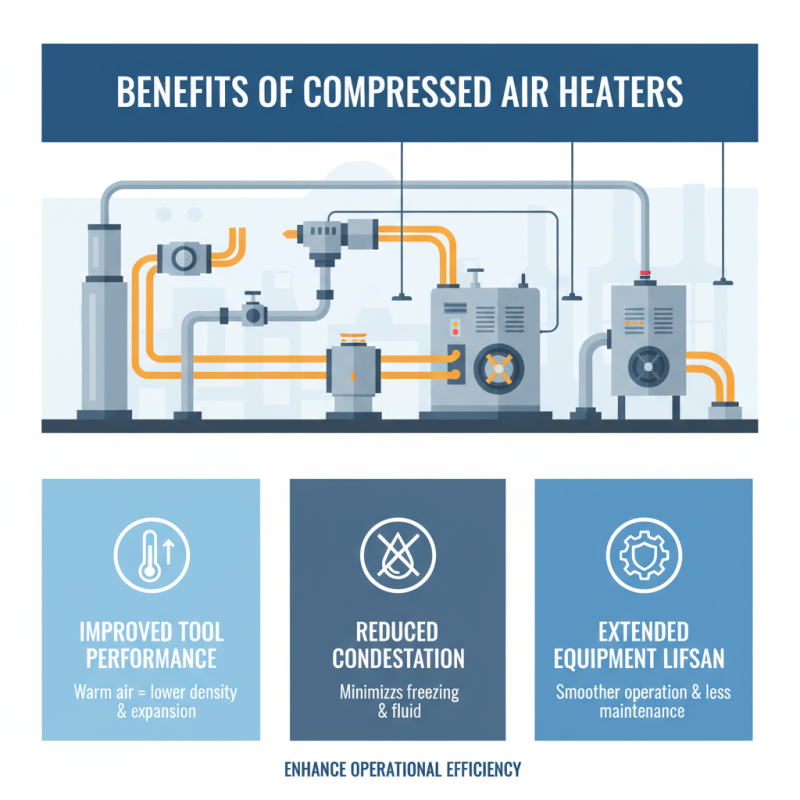

In industrial applications, utilizing a compressed air heater offers numerous benefits that can significantly enhance operational efficiency. By raising the temperature of compressed air, these heaters facilitate improved performance for pneumatic tools and machines. Warm air has a lower density and expands, which helps in reducing condensation in air lines and equipment. This not only minimizes the risk of freezing and fluid accumulation but also promotes smoother and more reliable functioning of pneumatic systems, thereby extending equipment lifespan and reducing maintenance costs.

Additionally, compressed air heaters play a crucial role in energy efficiency. By preheating the compressed air before it enters the system, industries can optimize energy consumption, leading to lower utility costs. This preheating reduces the workload on machinery, enabling systems to operate more efficiently. Furthermore, by maintaining a stable air temperature, companies can enhance production rates and ensure consistent quality in manufacturing processes, resulting in greater overall productivity. Overall, the implementation of compressed air heaters in industrial settings not only boosts efficiency but also contributes to sustainable operational practices.

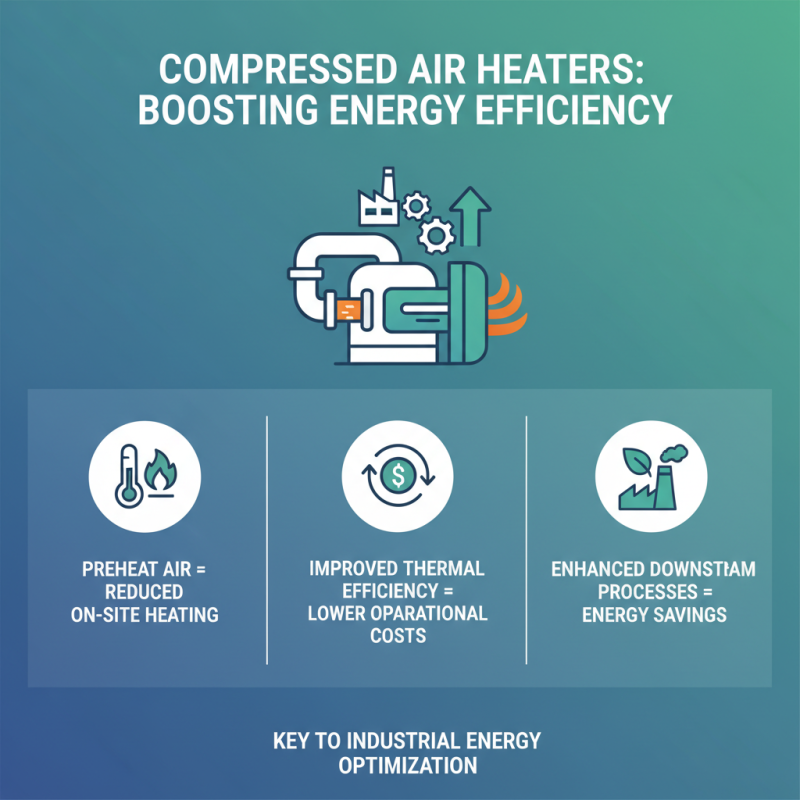

Compressed air heaters play a crucial role in enhancing energy efficiency in various industrial applications. By raising the temperature of compressed air before it enters a process, these heaters reduce the energy consumption associated with heating air on-site. This pre-heating process allows for improved thermal efficiency, which in turn minimizes wasted energy and lowers operational costs. Furthermore, when heated air is used, it can improve the efficiency of downstream processes, such as drying and material handling, leading to significant energy savings over time.

In addition to direct energy savings, compressed air heaters can also enhance overall system performance. By maintaining a consistent temperature, they help minimize moisture and condensation within compressed air systems, which can lead to increased reliability and decreased maintenance costs. This moisture control not only protects equipment but also ensures that the quality of the final product is not compromised. Additionally, efficient thermal management throughout the compressed air system can lead to longer equipment lifespan and reduced energy losses, further solidifying the importance of implementing compressed air heaters in energy-conscious environments.

When selecting a compressed air heater, several key features should be taken into account to ensure optimal efficiency and performance. One of the primary considerations is the heater's temperature control capabilities. Advanced models offer precise temperature regulation, enabling users to maintain consistent air temperatures, which is crucial for applications requiring specific heat levels. According to industry reports, precise temperature management can improve the efficiency of downstream processes by up to 20%, highlighting the importance of choosing a heater that supports this feature.

Another significant factor is the heater's energy efficiency rating. Compressed air heaters can consume considerable amounts of energy, so selecting a model that offers high efficiency can lead to substantial cost savings. Data from the Compressed Air and Gas Institute indicates that utilizing energy-efficient heaters can reduce energy costs by approximately 25% over traditional heating methods. Furthermore, evaluating the material construction of the heater is essential; durable and corrosion-resistant materials can enhance the lifespan of the equipment, reducing the long-term costs of replacement and maintenance.

Finally, the heater's installation and maintenance requirements should be considered. Models designed for easy integration into existing systems can save both time and resources during setup. Regular maintenance is also a crucial aspect; heaters that allow for straightforward access to key components facilitate routine checks and repairs, thus minimizing downtime. Ensuring these key features are part of the selection criteria can significantly contribute to a facility's overall efficiency and productivity.

Compressed air heaters are vital in various industries where temperature control is essential for enhancing productivity and ensuring quality in manufacturing processes. In the automotive sector, for instance, compressed air heaters are utilized to maintain optimal temperatures during paint spraying and drying processes. According to a report by the Compressed Air and Gas Institute, maintaining a consistent air temperature can lead to a 25% increase in paint adhesion and a reduction in defects, resulting in significant savings on rework costs.

In the food and beverage industry, compressed air heaters play a crucial role in packaging and processing. The use of heated compressed air helps to eliminate moisture, which can degrade packaging materials and affect product shelf life. Data from industry studies indicate that temperature control in air drying processes can improve efficiency by up to 30%, ensuring that products remain fresh and safe for consumption. The pharmaceutical industry also benefits from compressed air heaters, as they help maintain sterile conditions during manufacturing and packaging, reducing the risk of contamination significantly.

These applications highlight the versatility of compressed air heaters across different sectors. The efficiency they bring not only enhances product quality but also contributes to significant energy savings. Firms looking to optimize their production processes can leverage these heaters to achieve better control over their operations while meeting stringent industry standards.

Regular maintenance is crucial for ensuring the optimal performance of compressed air heaters. One of the simplest yet most effective maintenance tips is to routinely check and clean the air filters. Clogged or dirty filters can restrict airflow, leading to inefficient heating and increased energy consumption. It's recommended to inspect the filters monthly and replace them as needed to keep the system running smoothly.

Another essential aspect of maintenance is monitoring the heater’s temperature settings and operational pressures. Fluctuations can indicate underlying issues, such as leaks or malfunctioning components, which should be addressed promptly to avoid larger problems. Additionally, scheduling periodic professional inspections can help identify potential issues early, ensuring the heater operates at peak efficiency and prolonging its lifespan.

Lastly, it’s important to keep the surrounding area clean and free from dust and debris. This prevents contaminants from entering the system and improves overall performance. By adhering to these maintenance practices, users can maximize the efficiency of their compressed air heaters, ultimately leading to lower operational costs and improved reliability in their applications.

| Benefit | Description | Key Consideration | Maintenance Tip |

|---|---|---|---|

| Energy Efficiency | Heats air efficiently, leading to lower operational costs. | Ensure the heater is the right size for your application. | Regularly check and clean filters to maintain airflow. |

| Consistent Temperatures | Maintains stable temperatures for processes sensitive to heat fluctuations. | Monitor temperature settings regularly for accuracy. | Inspect heater elements for wear and replace as needed. |

| Improved Air Quality | Heated air can help reduce humidity and contaminants. | Use with proper filtration systems to maximize air quality. | Perform annual maintenance checks on filtration components. |

| Versatility | Can be used in various applications including drying, curing, and processing. | Select heaters that can adapt to different applications. | Calibrate for different applications to ensure performance. |