Leave Your Message

In industrial settings, maintaining optimal air temperature is crucial. Experts like Dr. Emily Roberts, a leading specialist in thermal technologies, emphasize that "A Compressed Air Heater can significantly enhance efficiency and production." This technology warms compressed air, improving performance in various applications.

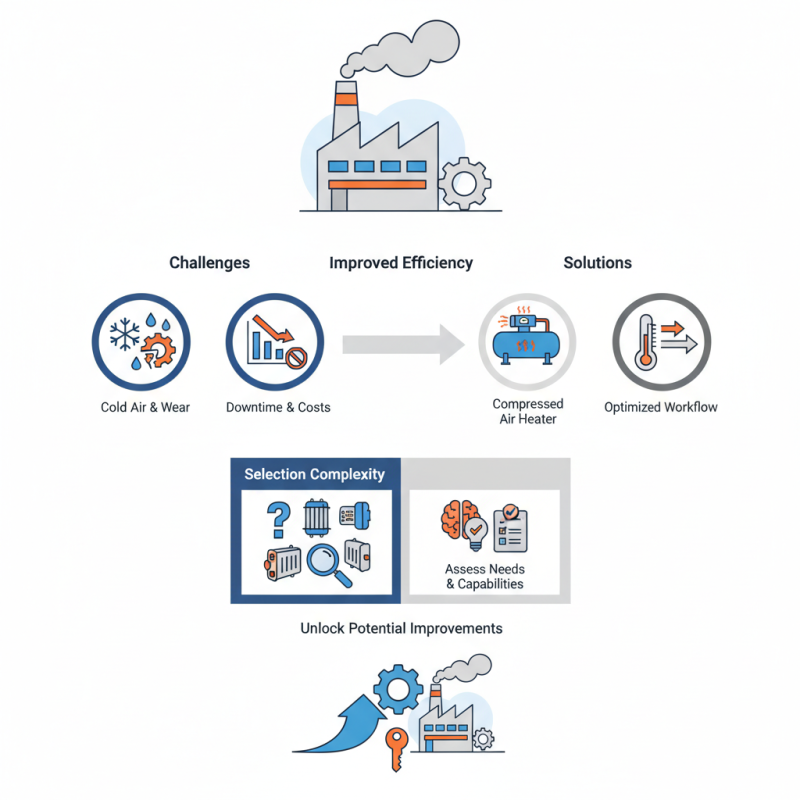

Many industries face challenges when using compressed air systems. For instance, cold air can lead to condensation and equipment wear. A Compressed Air Heater addresses these issues directly. It raises air temperatures, ensuring better workflow and preventing costly downtime.

However, selecting the right heater can be complicated. Not all heaters are the same; some models may not fit every application. Companies must assess their specific needs carefully. While a Compressed Air Heater can be beneficial, understanding its capabilities and limitations is vital. This thoughtful approach can unlock potential improvements in industrial processes.

Compressed air heaters are gaining traction in industrial applications. They enhance efficiency and provide numerous benefits. One significant advantage is

energy savings. According to a recent report by the Energy Efficiency Industrial Association, compressed air heating can reduce energy costs by up to 30%. This is especially beneficial for industries that rely heavily on compressed air systems.

Temperature control is another key benefit. Proper heating ensures the right temperature for operations, which prevents condensation. This is crucial in avoiding equipment damage and maintaining product quality. In fact, a survey conducted by the Industrial Heating Association showed that 65% of companies experienced improved product reliability after implementing compressed air heaters.

Tips: Always monitor the heater's performance. Regular checks can prevent energy waste. Consider the specific heating needs of your processes; this can guide your choice on heater size and configuration. Lastly, staff training is vital. Ensure your team understands proper usage to maximize benefits.

However, not all systems are perfect. Some installations may require higher upfront costs than traditional systems. Also, inadequate maintenance can lead to inefficiencies. Balancing upfront investment with long-term savings requires careful thought.

Compressed air heaters play a vital role in enhancing operational efficiency across various industrial applications. These heaters raise the temperature of compressed air before it reaches production equipment. By doing so, they prevent condensation, ensuring a consistent and reliable airflow. This leads to improved performance in pneumatic tools and machinery. A smoother operation often results in less downtime, a crucial factor for any production line.

Moreover, maintaining an optimal air temperature can directly impact energy consumption. Cooler air requires more energy to compress, leading to higher operational costs. With a compressed air heater, consistently warm air means energy savings. Workers appreciate the results, but it’s not perfect. Challenges can arise with maintenance and the initial setup. Regular checks are essential to ensure the system runs efficiently over time.

Investing in compressed air heaters also demands a careful analysis of your specific needs. Each facility has unique requirements. Understanding your operations helps refine the selection. Inevitably, some facilities may find that the balance of investment and return isn’t where they’d hoped. It may take time to identify the right solutions within the broader context of industrial heating technology.

When selecting a compressed air heater for industrial applications, several key features deserve attention.

Temperature control is crucial. The heater should provide accurate and stable temperature regulation.

Inconsistent heat can lead to product defects or inefficient processes. Easy temperature adjustments are essential for various applications.

Look for models with user-friendly interfaces.

Capacity is another important aspect. Your heater must match your operation's requirements.

A unit that's too small will struggle, causing delays. Conversely, an oversized heater wastes energy.

Understand your air volume needs. Then, choose a heater with the right specifications.

Energy efficiency cannot be overlooked. Heating compressed air consumes significant power. Opt for units designed to minimize energy loss.

This can substantially reduce operational costs. Consider maintenance requirements as well. Heaters need regular checks to ensure optimal performance.

A model that’s complex may lead to higher maintenance costs. Prioritize reliability in your choice.

Neglecting these factors may result in headaches down the line.

Compressed air heaters find significant usage across various industries. They are essential in processes requiring heated air. For instance, plastics manufacturing benefits from heated air for drying and molding. It enhances production efficiency.

Another application is in the food industry. Here, compressed air heaters help maintain the right temperature during packaging. It ensures product quality and extends shelf life. Efficient heating can also be crucial in chemical processing. Many reactions need a specific temperature to proceed correctly.

Tips: Always monitor the air temperature, ensuring it meets the requirements of your process. This can prevent unwanted breakdowns. Regular maintenance of heaters is also vital. It reduces the chance of unexpected failures.

In woodworking, heated air helps in drying lumber. The right temperature accelerates drying times while preventing warping. However, adjusting the heat settings can be tricky. Too much heat may damage the wood. Finding the right balance is essential.

These examples highlight the diverse applications of compressed air heaters. Each industry has unique challenges. A thorough understanding of these needs will better guide the selection of heating solutions.

Compressed air heaters play a crucial role in various industrial applications. They ensure that compressed air reaches optimal temperatures for efficient operation. Regular maintenance is key to maximizing the performance of these heaters. One important tip is to check the filters frequently. Dirty filters can reduce airflow and efficiency. It's essential to replace or clean them regularly. This simple step can have a significant impact.

Another aspect to consider is the heater's alignment. Misalignment can cause uneven heating. This issue often leads to more significant problems down the line. Inspect connections and ensure everything is properly aligned. Additionally, monitor the temperature settings. If they fluctuate too much, it could indicate a problem with the heater. Early detection allows for timely repairs.

Lastly, remember to inspect the insulation around the heater. Damaged insulation can lead to heat loss. This wasted energy not only affects performance but also increases costs. Regular checks will help maintain efficiency and reduce unnecessary expenses. A well-maintained compressed air heater can improve productivity significantly. Small adjustments today can lead to better results tomorrow.