Leave Your Message

In a world where industrial efficiency is paramount, understanding how to maximize the output of your systems can significantly enhance productivity and reduce operational costs. One crucial yet often overlooked component in many manufacturing and processing setups is the Compressed Air Heater. These devices play a key role in optimizing the performance of compressed air systems by ensuring that the air delivered is at the right temperature, which helps in preventing moisture buildup and improves overall system efficiency. This blog will present five essential tips on how to effectively use and maintain your Compressed Air Heater for peak performance. Whether you are looking to improve energy efficiency, prolong the lifespan of your equipment, or enhance the quality of your outputs, these tips will provide you with practical insights to get the most out of your compressed air heating systems.

Compressed air heaters are becoming increasingly vital in industries where temperature control is crucial for optimal performance. According to a recent report by the Compressed Air and Gas Institute (CAGI), properly heated compressed air can enhance process efficiency by up to 25%. This is particularly significant in applications such as drying, curing, and material handling, where the correct temperature can prevent bottlenecks and enhance product quality.

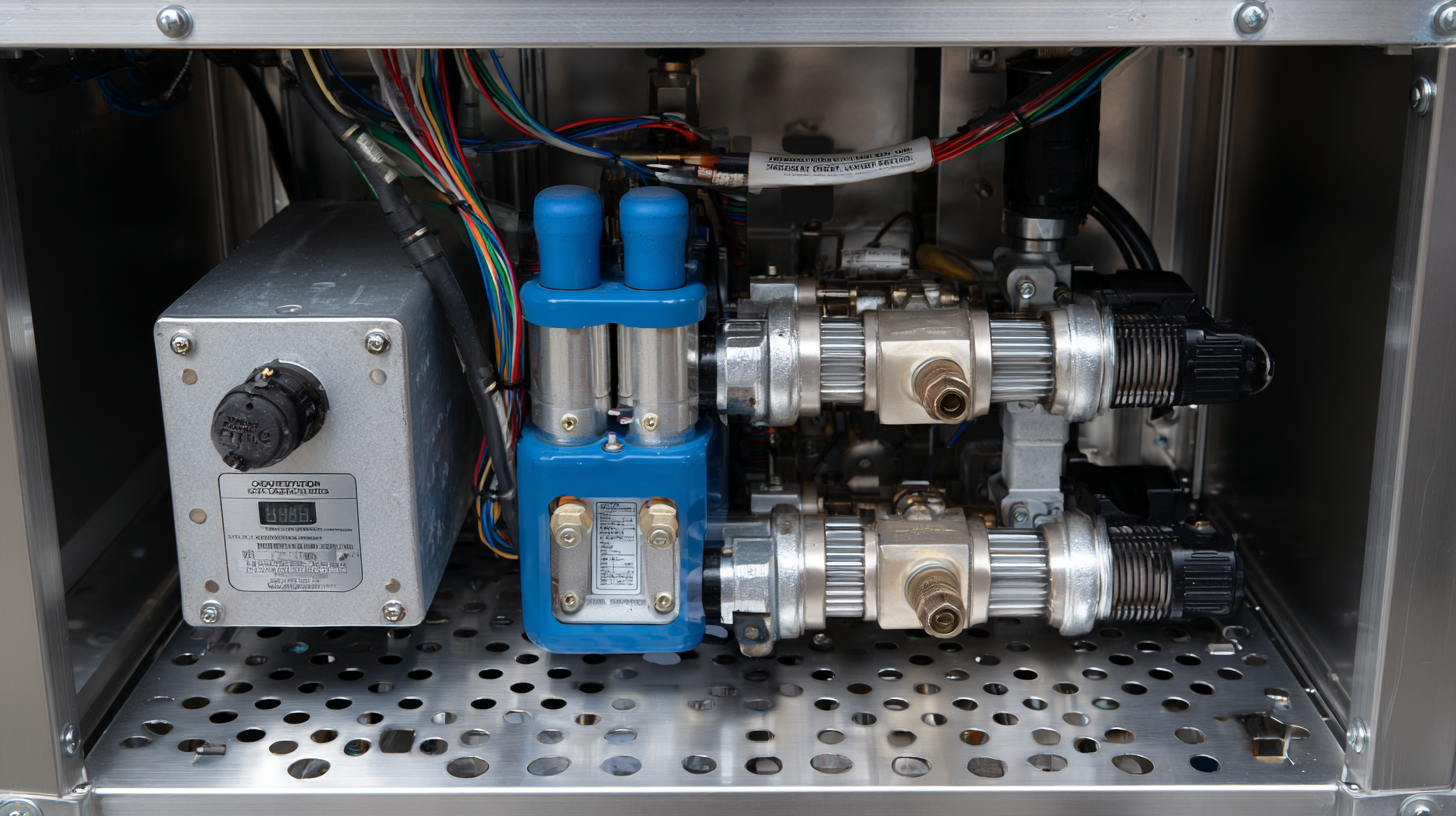

Understanding the mechanics of compressed air heaters is fundamental. These devices work by raising the temperature of compressed air before it enters operational tools and equipment. A 2022 study published by the International Journal of Thermal Sciences indicated that systems utilizing pre-heated compressed air showed a marked reduction in energy consumption—saving up to 30% in energy costs compared to untreated air. With such compelling evidence, it’s clear that an investment in compressed air heating technology can yield impressive returns on efficiency and operational cost savings.

This chart illustrates the estimated percentage improvement in efficiency when implementing essential tips for maximizing the performance of compressed air heaters. Proper insulation and right sizing significantly contribute to enhanced efficiency, while managing air leaks also plays a critical role.

When it comes to selecting the right type of compressed air heater for your applications, understanding the specific needs of your operation is crucial. Different types of heaters, such as electric, gas-fired, and indirect-fired heaters, each offer unique advantages depending on the nature of the work. For example, electric heaters are often chosen for their efficiency and ease of installation in small to medium-sized facilities, while gas-fired options may be more suitable for larger operations requiring higher heat output. Evaluating your facility's space, the volume of compressed air needed, and regulatory compliance are key factors in making an informed choice.

Additionally, consider the operational environment where the heater will be used. In applications where air purity is essential, indirect-fired heaters can provide a significant advantage, as they minimize the risk of contamination from exhaust gases. It's also vital to assess the heater's compatibility with your existing equipment and whether it can efficiently integrate into your production processes. By taking these factors into account, you can ensure you select the right compressed air heater, optimizing efficiency and enhancing the overall productivity of your operations.

When it comes to maximizing the efficiency and longevity of compressed air heaters, proper maintenance is key. Regularly inspecting and cleaning filters is essential to ensure that air can flow freely through the system. Clogged filters not only reduce efficiency but can also lead to overheating. Make it a habit to check and replace filters according to the manufacturer's recommendations, or more frequently if your system operates in a particularly dusty or contaminated environment.

In addition to filter maintenance, it’s crucial to monitor the heater's temperature and pressure settings. Keeping these parameters at optimal levels can prevent undue stress on the system, which can lead to premature failures. Routine checks on seals and connections are also important; any leaks can compromise performance and energy efficiency. Implementing a preventative maintenance scheduling can help you catch issues before they escalate, ensuring your compressed air heater operates smoothly and effectively for years to come.

When integrating energy efficiency into compressed air heating systems, it's essential to focus on optimizing both the equipment and operational practices. One effective strategy is to routinely audit and maintain your heating system. Regular checks ensure that the components are functioning at peak performance, preventing energy loss due to leaks or faulty parts. Investing in high-quality filters and moisture separators can significantly improve efficiency by maintaining the integrity of the compressed air. This not only enhances the system's performance but also prolongs the lifespan of the equipment.

Another key strategy is the implementation of smart controls and monitoring systems. These technologies allow for real-time adjustments based on demand, ensuring that the compressed air heaters operate only when necessary. By utilizing programmable logic controllers (PLC) or automated controls, facilities can reduce unnecessary energy consumption during off-peak hours. Additionally, integrating heat recovery systems can capture excess heat generated during the heating process, redistributing it to other parts of the facility, thus maximizing energy use and further lowering operational costs.

| Tip | Description | Expected Energy Savings (%) | Implementation Difficulty |

|---|---|---|---|

| Regular Maintenance | Routine checks and cleaning of systems to ensure optimal performance. | 10-15% | Low |

| Insulation | Apply adequate insulation on pipes to reduce heat loss. | 20-30% | Medium |

| Heat Recovery Systems | Integrate systems that capture waste heat for reuse. | 25-50% | High |

| Optimize System Controls | Use advanced controls to monitor and adjust temperature settings automatically. | 15-25% | Medium |

| Variable Speed Drives | Implement variable speed drives on compressors to match airflow with demand. | 10-20% | High |

When it comes to maximizing efficiency with compressed air heaters, avoiding common mistakes is crucial. One prevalent error is setting the temperature too high, which can lead to energy waste. Many users mistakenly believe that hotter air equals better performance; however, an optimal temperature setting ensures that the heater operates efficiently without overloading the system. Regular maintenance, such as cleaning filters and inspecting connections, is often neglected, which can degrade performance over time.

Another mistake is failing to use the appropriate size and type of compressed air heater for your specific needs. Using a heater that is too small will struggle to maintain warmth, while an oversized unit consumes unnecessary energy. Additionally, users often overlook proper insulation of the heated area. Drafts and insufficient insulation can easily negate the benefits of a compressed air heater, as heat escapes, forcing the unit to work harder and consume more energy. By avoiding these common pitfalls, you can enhance efficiency and ensure consistent performance from your compressed air heating system.