Leave Your Message

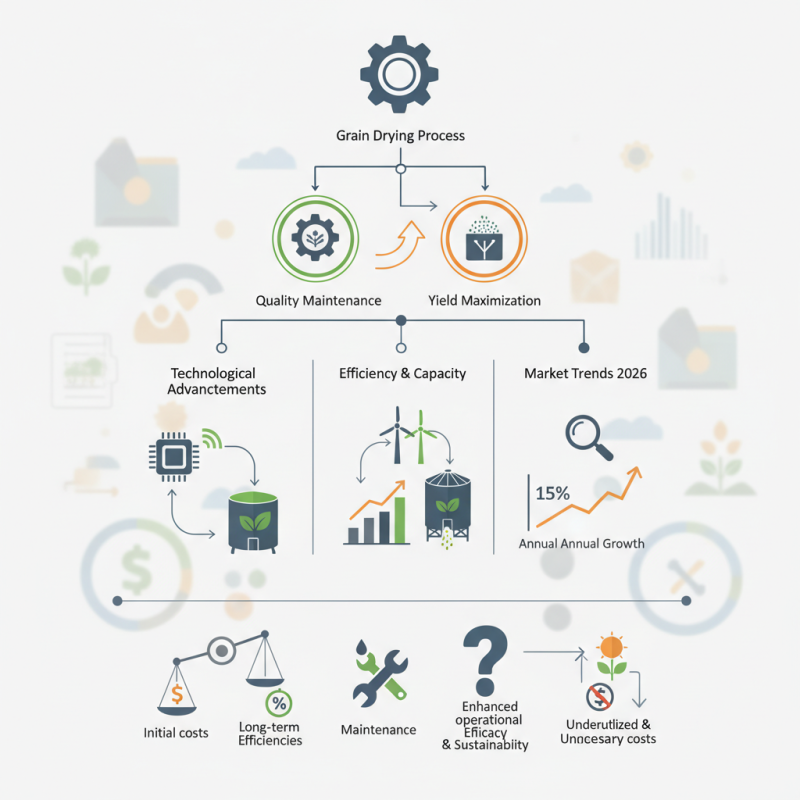

The grain drying process is crucial for maintaining quality and maximizing yields. In recent years, advancements in technology have led to innovative grain dryer options. A report from the USDA states that efficient grain drying can reduce spoilage rates by up to 20%. Selecting the right grain dryer can significantly impact profitability.

Different dryer models vary in energy efficiency and drying capacity. For instance, high-capacity dryers are specially designed to handle large volumes of grain. According to a recent market analysis, the demand for energy-efficient models is increasing, with a projected growth of 15% annually. However, not all options align with every farm's needs. Some systems may be underutilized, leading to unnecessary costs.

Farmers often report difficulty in choosing the best grain dryer. It is essential to weigh both initial costs and long-term efficiencies. Many overlook maintenance expenses as well. It's critical to reflect on whether the selected machine will truly enhance operational efficacy. The future of grain drying relies on making informed decisions that prioritize efficiency and sustainability.

Grain dryers play a crucial role in agriculture. They help maintain grain quality by reducing moisture levels. This process is vital for preventing spoilage during storage. Without proper drying, harvested grain can deteriorate quickly. Farmers must prioritize this equipment for sustainable production.

Choosing the right grain dryer requires careful consideration. Factors like capacity, energy efficiency, and drying speed come into play. Many options are available, but not all may fit specific needs. The wrong choice can lead to wasted resources and loss of product quality. Evaluating efficiency can be challenging. Farmers should keep track of their drying operations to identify areas for improvement.

Maintenance of grain dryers is often overlooked. Regular checks on filters and fans can prevent costly breakdowns. Ignoring this can result in decreased performance. Additionally, operators should continually assess their drying practices. Adapting to new techniques and technologies may enhance efficiency. Grain drying is not just about equipment; it’s about optimizing processes for better yields.

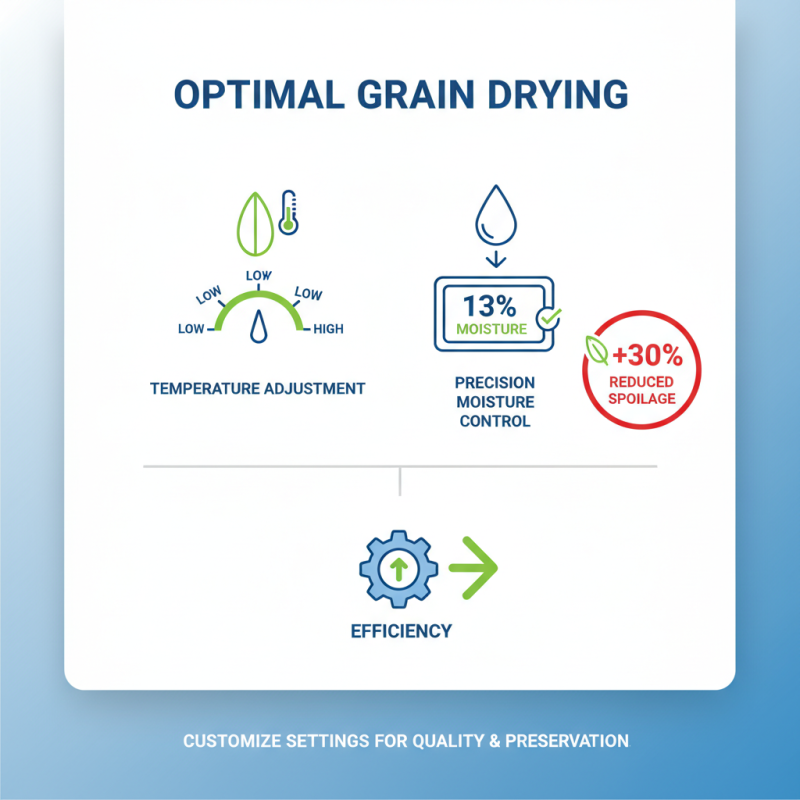

When looking for top grain dryer options, several key features can enhance efficiency. A well-designed dryer should have adjustable temperature settings. This allows users to customize the drying process according to the type of grain. Precision moisture control is crucial as well. Studies show that maintaining a moisture level of 13% or lower can reduce spoilage by 30%. Users must prioritize these adjustments.

Another important feature is energy efficiency. According to industry reports, energy-efficient dryers can reduce operational costs by up to 25%. Features such as automatic shut-off systems can prevent energy waste when grain is adequately dried. Durable construction materials also play a role. They ensure long-term operation and reduce maintenance frequency.

**Tip:** Regularly calibrate your dryer for optimal moisture readings. It’s a small step that can lead to significant gains.

Consider the dryer’s size and capacity based on your operation scale. Too big, and you waste energy; too small, and you risk bottlenecks during peak harvest. Reflecting on these characteristics can lead to better decisions. The ideal grain dryer should not only meet current demands but also support future growth.

When selecting a grain dryer, energy efficiency is key. Various models claim to reduce costs while maximizing performance. However, not all options deliver the same results. Factors like airflow, heat transfer, and moisture removal determine efficiency levels. It’s crucial to understand these characteristics when making a choice.

Tips: Always check energy ratings. Look for models with lower kilowatt-hour usage. Compare the drying times of different units. This can reveal the real efficiency differences among models.

Some dryers may offer advanced features. They could have sensors to monitor moisture levels. Yet, sometimes, these features may not work as well as advertised. Users report inconsistent performance in varying humidity conditions. This can leave room for improvement in many systems. Don’t rely solely on technology; regular maintenance is essential.

Tips: Maintain your dryer regularly. Clean out debris that can block airflow. This simple step can keep efficiency high and avoid unnecessary costs. Monitor your operational patterns to identify any inefficiencies. Remember, the goal is to maximize output with minimal energy input.

| Model | Energy Consumption (kWh) | Drying Capacity (bushels/hour) | Efficiency Rating (Stars) | Price ($) |

|---|---|---|---|---|

| Model A | 150 | 40 | 4.5 | 10,000 |

| Model B | 120 | 35 | 4.0 | 9,500 |

| Model C | 130 | 45 | 4.7 | 11,200 |

| Model D | 140 | 50 | 4.2 | 10,800 |

| Model E | 110 | 30 | 4.8 | 9,000 |

Maintaining a grain dryer is crucial for optimal performance and efficiency. Regular inspections of moving parts can prevent unexpected breakdowns. Reports indicate that 25% of dryer failures stem from inadequate maintenance practices. Cleaning the dryer regularly can enhance airflow. Clogged systems reduce efficiency significantly.

Consider the temperature settings for drying. Overheating can damage grains. A study shows that 10% of grains lost energy efficiency due to excessive heat during drying. Monitoring moisture levels is essential. Adjusting settings can save energy and extend equipment life.

Moreover, it's essential to train operators. Skilled personnel can identify minor issues before they escalate. Inadequate training is often overlooked. It can lead to costly repairs and downtimes. Proper documentation of maintenance activities also aids in tracking performance trends. Ultimately, investing time in routine checks pays off.

This chart illustrates the efficiency and energy consumption of top grain dryer models in 2026, along with their typical maintenance frequency. The data indicates that optimal grain dryers achieve up to 90% drying efficiency while requiring regular maintenance.

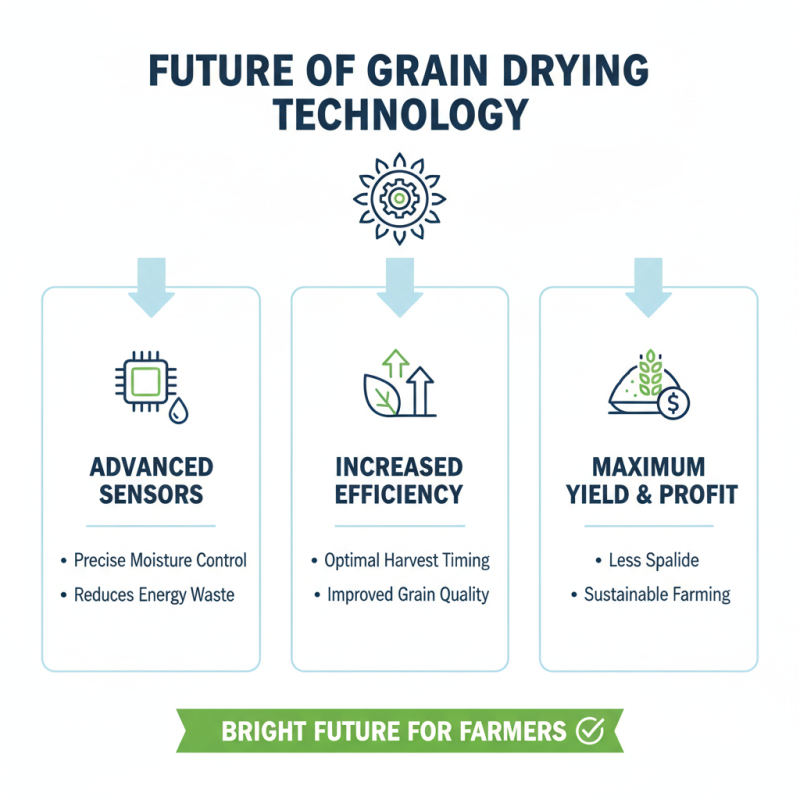

The future of grain drying technology is bright. Innovations are making processes more efficient. Advanced sensors are emerging, offering precise moisture control. This reduces energy waste and improves grain quality. Farmers can harvest at optimal times, ensuring maximum yield.

Artificial intelligence is revolutionizing grain drying. Smart systems analyze data in real-time. They adjust drying conditions automatically. This not only saves time but also minimizes human error. However, the challenge lies in integrating these technologies with existing systems.

New materials are being explored for construction. Lightweight composites and improved insulation can enhance drying performance. Yet, adaptation to these materials presents a hurdle. Training staff to operate advanced machines poses another challenge. Questions around sustainability linger, requiring careful consideration.